ISO 9001 – requirements of clause 6

Once the organisation understands its context and secured senior management’s involvement in the process, it can then plan for the implementation of the Quality Management System (QMS). Requirements Of Clause 6 – Planning is a process of logical thinking and making rational decisions before acting. It is a critical step to set-up an effective management system and ensure its continual improvement. While planning for the QMS, organisations should consider their internal and external issues, interested parities and their needs and expectations and the scope of the management system.

- Actions to address risks and opportunities

- Quality objectives and planning to achieve them

- Planning for changes to the QMS

6.1 Actions to address risks and opportunities

Risks are the effect of uncertainty, which can influence the organisation in positive or negative way. Organisations should take proactive approach in regards to the risks and opportunities, which means that they are expected to identify major risks, determine when they might occur, and define who will be taking actions to address them. To achieve the purpose of the requirements of Clause 6, organisations should apply their risk assessment methodology consistently and effectively. There is no requirement for a formal documented risk management procedure in the requirements of Clause 6, but organisations should confirm that they have a methodology in place to effectively identify and address risks and opportunities in their QMS. Opportunities can be considered as positive effects of risks that can provide benefits to the current processes and intended outcomes. Some sources to identify risks and opportunities can include internal and external issues, relevant needs and expectations of interested parties, compliance obligations, past experience, emerging technologies, learning from competitors, observations and interviews. Once the risks are identified and their likelihood and impacts have been determined, organisations should define controls to manage these risks. Risk control methods are often grouped into the following categories:- Avoidance: change the plan to eliminate the threat. Refuse to accept the risk.

- Reduction: reduce the likelihood or consequences of the risk.

- Retention: accept the risk and exposure with no further action to manage – often for low risks.

- Transfer: shift responsibility and consequences to another party, though the risk still exists.

ISO 9001 Clause 6.2 – Quality Objectives And Planning To Achieve Them

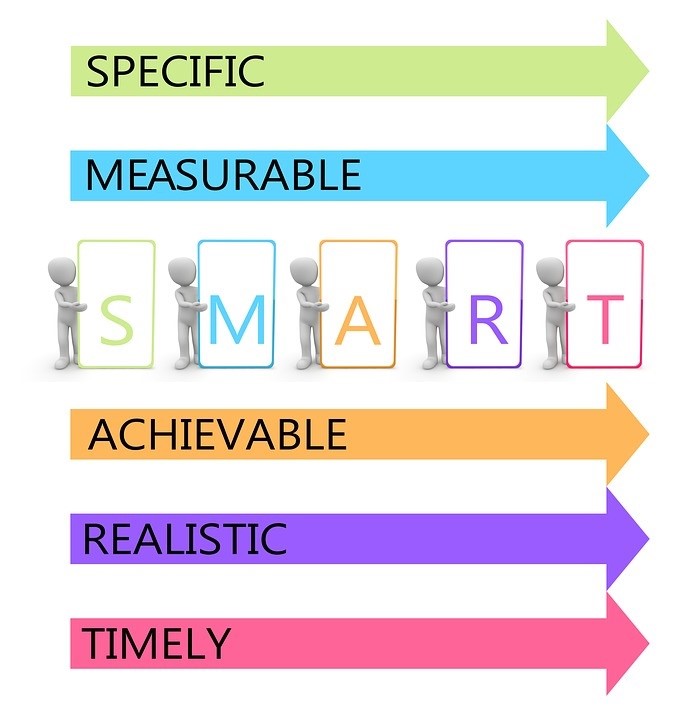

Quality objectives are high-level targets to enhance the quality performance of the company. Organisations use these objectives to change the commitments defined in their quality policy into measurable plans of action. Quality objectives should be established at relevant levels and functions of the organisation to support and improve processes of the QMS. Defined objectives should be Specific, Measurable, Achievable, Realistic, and Time-oriented (SMART).

- Achieve a 20% reduction in production defects

- Increase the annual training budget by 10%

- Comply with a cumpulsory/voluntary requirement within six months

- Improve on-time deliveries by 25%

- Improve purchasing procedures by employing a new purchasing officer

- Quality objectives should be consistent with the quality policy of the organisation.

- Take into account compliance obligations and needs and expectations of interested parties.

- Where possible, appropriate quantitative indicators should be determined to measure achievements and effectiveness of quality objectives.

- Defined objectives should be communicated throughout the organisation and being updated as appropriate.

ISO 9001 Clause 6.3 Planning Of Changes

To keep pace with the evolving business environment, organisations are likely to make changes in their structure, processes, products, people, and culture. Changes that can have a noticeable impact on the organisation’s QMS might arise due to:

- New products, services, and processes

- Changes to existing products, services, and processes

- Changes to the compliance obligations of the organisation

- Corrective and improvement actions,

- Changes to the scope and context of the organisation

Changes can bring risks and these risks should be managed properly to ensure efficiency of the QMS. Changes are intended to be beneficial but they need to be carried out when determined by your organization as relevant and achievable. Organisations should consider the following before approving the changes to their QMS:

- The purpose of the change and potetnial risks it can brought

- Integrity of the QMS and potential impacts of the change on the current processes

- Availability of the required resources

- Allocation and reallocationb of responsibilities and authoritise

Before approving the plan, it is important to ensure that everything has been covered by checking that there are no issues needed to be addressed.When changes are planned, top management should communicate changes to workers are relevant levels and make them aware of the potential effects on their work. In the case of unintended changes, organisations should review the consequences and take necessary actions to mitigate any adverse effects.

Conclusion

In conclusion, requirements of Clause 6 within ISO 9001 isn’t just a checklist; it’s a compass guiding organizations toward excellence. Planning isn’t merely a phase but a mindset, ingrained in every decision and action. By embracing the essence of Clause 6, businesses not only meet compliance but also fortify themselves for dynamic landscapes.

Understanding risks, seizing opportunities, defining SMART objectives, and navigating changes—these are the pillars that uphold a resilient Quality Management System. It’s about weaving quality into the fabric of the organization, aligning objectives with policies, and being agile in the face of change.

As we close this exploration for requirements of Clause 6, remember that ISO 9001 isn’t just a badge; it’s a commitment to quality, improvement, and customer satisfaction. Continual review, adaptation, and a forward-thinking approach will not only ensure compliance but also drive success in an ever-evolving marketplace. Embrace Clause 6, not as a requirement, but as a catalyst for organizational excellence and sustained growth.

ISO 9001 Clause 6.2 And 6.3| Clause 6 Part Two

October 27, 2021[…] In What are the requirements of clause 6 – part one, we learnt about risks and opportunities in planning, now we are going to learn about ISO 9001 clause 6.2, quality objectives and clause 6.3, planning of changes. […]